Industry news

Only provide you with exclusive product solutions with strong practical performance

Current position:home > NEWS > Industry news

Current position:home > NEWS > Industry news

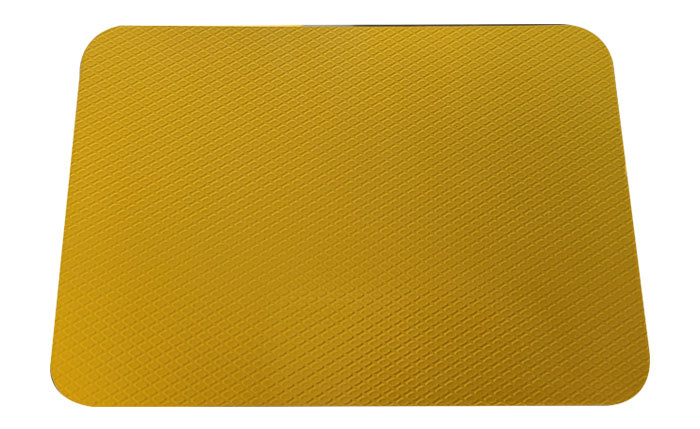

What does the standard of choose and buy of coloured aluminium sheet have

2020-02-19 10:14:00

After color aluminum after a series of processing, of course, we can't guarantee every product is absolutely no problem, will certainly exist, the vulnerability of the before to the factory, relevant operators will check, the process inevitably some omissions, so everyone in choosing a product, be sure to polish eyes, then we study the choose and buy of it under the standard together.

1. Cracks, corrosion and edges are not allowed on the surface of the colored aluminum plate, and diffusion spots are not allowed on the surface of the plate with thickness greater than 0.6mm;

2, the surface of the plate is allowed to have slight over pressure scratches, metal and non-metal indentation, insertion, scratch, roll printing, loose dendritic pattern and emulsion marks and other defects. However, the depth of each defect shall not exceed the allowable negative deviation of the thickness of the color aluminum plate, and ensure the minimum thickness;

3. The total bubble area should not exceed 100mm2 per square meter of plate surface;

4. Process aluminum clad sheet, with or without exposed parts of cladding layer and surface bubbles;

5, color aluminum plate defects are allowed to use 400 sandpaper for inspection grinding, its grinding depth shall not exceed the thickness of the allowable deviation; The edge of plank should be cut neat, without burr.

In addition, there is a very important point, the interior of the mirror aluminum plate is not allowed to have a central layer and crack, consumers must be carefully checked when buying.

Color aluminum plate as decorative materials, its quality is very important, and we are in the purchase, we must carefully check whether there is any damage or quality problems.

In the previous:How is the surface of the printed plate protected

The next article:Aluminum magnesium manganese plate how to install